0-8 mm Mineral Powder Process

| Capacity: | 10-100 t/h |

| Finished size: | 80mm |

| Application: | metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries, etc. |

| Shipping ports: | Shanghai |

| Delivery: | 20-30 days after receive deposit |

Overview

Application of 0-8 mm Mineral Powder Process:

0-8mm Mineral Powder process(European version coarse grinding line) is engaging in crushing various rocks and stones(such as Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, quartz, active carbon,glass ect) with comprehensive strength not higher than 320 MPa into coarse powder and small particles, it is widely used in metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries.

Structure and Working Process:

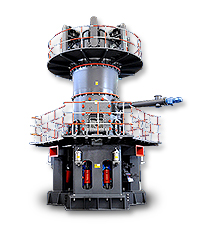

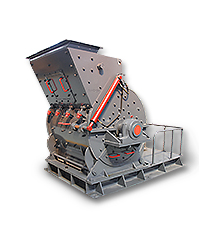

European version coarse grinding mill mainly consists of frame, rotor, support iron and grate bars. The frame is divided into two parts: upper part and lower part, which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of turn plates, pin shafts, and hammers which are grouped regularly in the main shaft.

For each parts, we will configurate different types and brand according to clients' practical needs.

The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers. Large materials entering the crusher through the feed inlet are firstly crushed by the high-speed hammers, and then thrown fiercely to the support iron for further crushing. Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirement. To avoid the plugging of the crusher, the proportion of water for the crushing materials is no more than 20%.