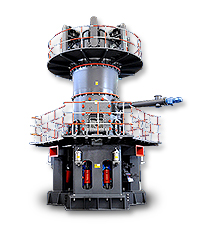

LXMC Ultra Fine Wet Stirring Mill

| Processing ability: | |

| Max feeding size: | 325mesh |

| Product Fineness: | <6000mesh |

| Range of application: | calcium carbonate, soft or hard kaolin, coal-water slurry, mica, barite, illite, gypsum, rare earth, magnesium oxide, aluminum oxide, red iron oxide, magnetic materials and so on |

Overview

LXMC ultra fine wet stirring mill Intorduction:

LXMC ultra fine wet stirring mill is widely used in grinding calcium carbonate, soft or hard kaolin, coal-water slurry, mica, barite, illite, gypsum, rare earth, magnesium oxide, aluminum oxide, red iron oxide, magnetic materials, and so on.The fineness can reach 2 microns with a 90% passing through rate per single mill one time. Products can be directly used for paper filler, coating, or after drying for coatings, paints, cosmetics, disposable diapers, plastic, PVC, and rubber filler, wire, and cable industries.

Mill feed particle size is 200-400 mesh, largest single machine can grind 2 microns or less D90 (6000 mesh) of the following products; Optimization of the length to diameter ratio for pulp residence time is long, the material running route is long, high crushing ratio, uniform particle size distribution, particle shape is spherical.

Benefit

LXMC ultra fine wet stirring mill Advantages:

• Ultra fine powders, the finest powders reach t o 2 micron with content 90% for milling one time.• Widely used in many industries.

• High productivity, high grinding efficiency, low energy consumption.

• Reliable and stable mechanical properties Vertical-shaped star wheel reducer higher transmission efficiency, run more smoothly.

• Low consumption of grinding media, non-polluting.

• The temperature is low for finished products, good liquidity.

• The components inside the mill with high hardness wear-resistant materials, long service life.

• Compact structure, suitable height, easy operation and maintenance, stable production, automatic controlling is optional.

Specifications

LXMC Ultra Fine Wet Stirring Mill Parameter:

Model: LXMC1000

Technical Specification:

|

Technique |

Single mill |

Two mills in Series |

|

|

Powder finness -2 micron |

D60 |

D90 |

D95 |

|

Solid content |

70%-75% |

70-75% |

70-75% |

|

Capacity per hour |

1.4-1.8 |

0.6-0.8 |

0.7-0.9 |

|

The dosage of dispersants(Kg/t) |

4 |

10 |

14 |

|

Grinding meson balls loss(Kg/t) |

0.2-0.4 |

0.5-0.6 |

0.8-1.2 |

|

Power consumption(KW/t) |

<45 |

<130 |

<170 |

Model: LXMC3600

Technical Specification:

|

Technique |

Single mill |

Two or more mills in series |

||

|

Powder finness -2 micron |

D60 |

D90 |

D95 |

D98 |

|

Solid content |

70-76% |

70-76% |

70-76% |

70-76% |

|

Capacity per hour (dry materials) |

3-3.8 |

1-1.5 |

1.8-2.2 |

1.5-1.8 |

|

The dosage of dispersants(Kg/t) |

4 |

8 |

12 |

15 |

|

Grinding meson balls loss(Kg/t) |

0.3-0.4 |

0.5-0.6 |

0.8-1.0 |

0.8-1.2 |

|

Power consumption(KW/t) |

<40 |

<125 |

<145 |

<180 |

Model: LXMC5600

Technical Specification:

|

Technique |

Single Mill |

Two or more mills in series |

|

|

Main unit quantity |

One mill |

Two mills |

Three mills |

|

Solid content |

70%-76% |

70%-76% |

70%-76% |

|

Powder finness -2 micron |

D60 |

D75 |

D98 |

|

Capacity per hour (dry materials) |

4.5-5 |

4.5-5 |

4.5-5 |

|

The dosage of dispersants(Kg/t) |

<5 |

<6 |

<15 |

|

Grinding meson balls loss(Kg/t) |

0.3-0.4 |

0.4 |

1-1.2 |

|

Power consumption(KW/t) |

<40 |

<50 |

<185 |