CLIRIK ultrafine mineral powder grinding mill for limestone

| Raw Material: | Limestone |

| Capacity: | 120,000 t/a |

| Feeding Size: | |

| Product Size: | 200 mesh, 400 mesh |

| Country of Client: | xingcheng |

Project profile

How to help customers improve the superfine powder industry chain? Clirik always takes technology as the core, responds to the market demand, improves and upgrades HGM ultrafine grinding mill machine, which can help you build a superfine powder production line with high production capacity, high performance, high environmental protection and high intelligence, and effectively enhance your market competitiveness.

Located in an industrial park in Xingcheng City, Xingcheng high calcium Co., Ltd. is a large-scale superfine powder production enterprise in Xingcheng city. The company has a research and development team with rich experience, high quality and strong professional skills, which is mainly engaged in research, processing, production and sales of mineral superfine powder, providing high-quality products and technical support for downstream customers. The company's products are sold all over the country.

The customer has a construction area of approximately 15,000 square meters and currently operates two high-end calcium carbonate powder production lines with an annual output of 120,000 tons. The finished calcium carbonate powder is widely used in power plants, building materials, cement mixing plants, asphalt mixing plants and other industries.

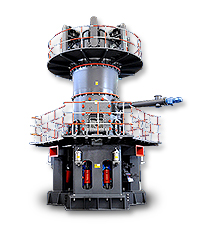

The customer is equipped with the CLIRIK HGM series of ultrafine powder grinding mills, which are designed for the new mineral powder processing technology. The products produced by CLIRIK ultrafine grinding mill have the advantages of high whiteness, stable color and uniform particle size distribution.

As an enterprise that always adheres to technology as the core, relying on the new market demand and improving the whole industry chain, the customer once again introduced the third generation HGM ultra-fine grinding mill of our company.

The equipment has carried out technical upgrading for the main machine grinding roller, powder separator, dust collector, reducer, main machine motor, fan and other accessories, which can effectively help customers build a high-capacity, high-performance, high-intelligence, and high-environmental ultra-fine powder production line, which effectively enhances the company's competitiveness in the local market.

A high-calcium company in Xingcheng will continue to adhere to the development concept of high quality and brand building, and work with CLIRIK to establish an integrated upstream and downstream industrial chain of ultra-fine powder, and strive to create a resource-saving enterprise.

Project Overview

Project name: High-end ultra-fine powder production line

Processing material: Limestone

Output: 120,000 tons

Finished product fineness: 200 mesh, 400 mesh

Finished product use:

1. 200 mesh: used in construction materials, cement mixing plants, asphalt mixing plants and other industries.

2. 400 mesh: used in power plant desulfurization powder, filler and other industries.

Optional equipment: HGM125 ultra-fine grinding mill

Project Benefits

1. Energy saving and environmental protection, green grinding

The dust of the production line is collected by a negative pressure dust removal system and placed in a fully enclosed finished product warehouse, which realizes no dust spillage, a clean production environment, and discharge conforms to international standards.

2. High cost performance, considerable investment income

The fine calcium carbonate particles produced by this project have excellent shapes and better quality after being modified by the CLG powder surface modifier. They are well received in the market and have a high profit per ton.

3. CLIRIK ultrafine grinding mill can run continuously for 24 hours

The reducer has circulating oil lubrication and circulating water cooling system to ensure the continuous operation of the ring roller mill for 24 hours.

4. Full-process service, saving time and worry

CLIRIK project design, equipment production, installation, commissioning, and after-sales service are integrated, and the whole process service is convenient for users, which has won time for the smooth commissioning of the project in a short time.

CLIRIK has been committed to the development and production of mineral mills and is one of the leaders in the field of ore crushing and grinding in China. We always adhere to the principle of taking technology as the core and customer first, and provide you with the most suitable and cost-effective mill.

Are you looking for a powder grinding mill? What material do you need to grind? You only need to leave your production needs, we will reply you within 24 hours, you can get a free planning plan, spend the least time to buy the most cost-effective mill.

You can browse more and get more about CLIRIK Powder Grinding Mills!